KUESTERS CALICO MACHINERY LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KUESTERS CALICO MACHINERY LTD.

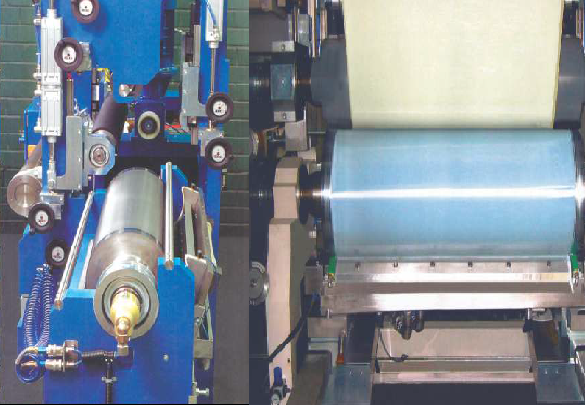

Coating Head

The Coating head is the first (and one of the most important) elements in determining the quality of the end product.

The quality of the end product results form perfect interaction between mechanical precision, innovative control login and Calico // Polytype’s know-how.

The precisely adjustable Calico // Polytype’s coating heads ensure reproducible quality.

Coating heads on movable trolleys can be outside the machine in preparation for production changes and then moved into working position in matter of minutes.

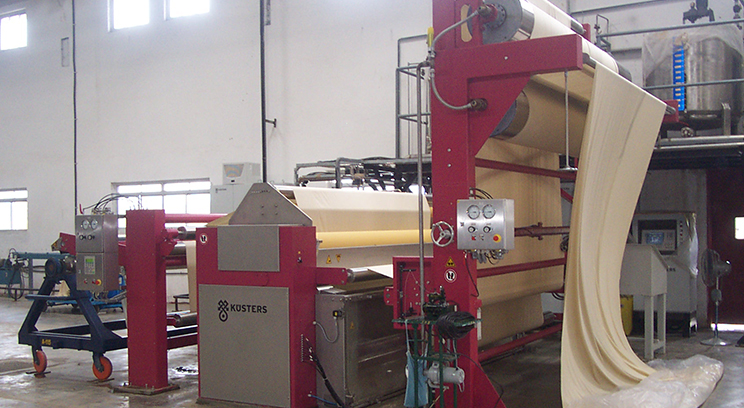

Pvdc Coating

Kusters Calico Machinery Pvt. Ltd. manufactures plastic converting machines, printing machines besides textile machines.

Converting Machinery for Plastics, Alu Foil, Paper

The machine for lacquering, colouring, coating, wet and dry laminating

High degree of operating comfort

Simplicity of maintenance

High productivity

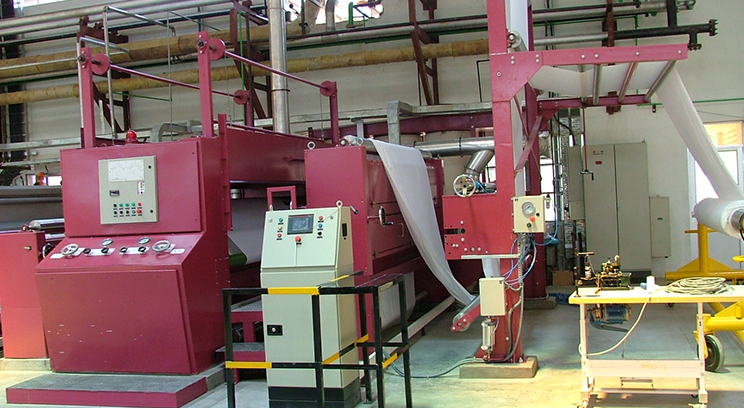

Solvent Base Lamination

With a particularly flexible design, these lines are configured to suit all the adhesive technologies in use to day.

Technology can be combined to meet individual customer requirements. The dying tunnel of primer and release coating units has been developed from practical data build up from installed machine. The Main design parameters are high output, high performance and energy efficient.

Calico // Polytype’s no waste winders are proven to product defect free self wound adhesive materials under production conditions.

Calico // Polytype’s film extrusion experience insures excellent web handling and control throughout the line.

The machine, which can include traditional solvent recovery systems ot as an alternative inert gas (nitrogen) solvent recovery and drying systems, is designed for full anti pollution control compliance.

Polymaster

Essence Of Excellence

Operator oriented design for fast change overs in short sequence of essential operations.

Web tension control high sensitive films

Gravure cylinder, inking system, are placed on as easy to operate quick slide in/out trolley system for quick change-over.

Three movement doctor blade with reference index. Quick replace machine for change of blades and blade holder.

Trolley change is simple without any tools required.

Sleeve type impression rubber roller system to reduce time.

Each dryer designed with higher efficiency and performance to control wastage and lessen power consumption. The advanced drying system with better airflow support least levels of solvent retention on the printed materials.

Hood opening allows access for cleaning and maintenance and cleaning ventilation rollers air nozzles

Superior advanced exhaust system.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.